Our equipment

Development of equipment according to our own design documentation and calculations, or according to the customer’s technical specifications.

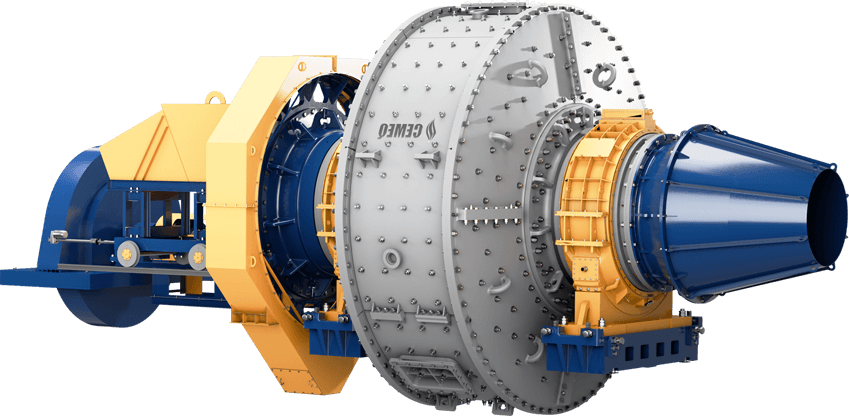

CEMEQ ASIA supplies technological equipment for industries in which the processes of crushing, grinding, drying, enrichment, and restoration of materials take place.

Our customers are enterprises of the mining, mining and processing industries, construction materials industries, metallurgical, chemical and petrochemical enterprises, as well as producers of mineral fertilizers, forest-industrial complexes.

Our customers are enterprises of the mining, mining and processing industries, construction materials industries, metallurgical, chemical and petrochemical enterprises, as well as producers of mineral fertilizers, forest-industrial complexes.

01

Projects

Development of working design documentation of any complexity

02

Certification

Compliance documents for all supplied equipment

03

Efficiency of communications

We will quickly calculate the cost of the project and give feedback

04

Control

We carry out quality control over the manufacture and supply of equipment