Development and implementation of automated control system projects

CEMEQ ASIA specialists successfully implement projects to automate new equipment and lines, reconstruct and modernize existing ones, replace hardware and develop new software.

CEMEQ ASIA's automated process control systems projects include various tasks, starting with electric drives and sensors of individual mechanisms and ending with the creation of an integrated process automation system using modern software and hardware complexes from well-known manufacturers.

The company provides a full range of services for automated control systems in industry:

- Design of automation systems. CEMEQ specialists carry out an extensive range of work on design of automation systems;

- Programming. We provide software development services for logic controllers and operator panels, as well as software development for automated workstations (AWS) using the SCADA software package;

- Design and manufacture of control cabinets. CEMEQ Company has its own production site to perform a full range of control cabinet assembly work. The assembly is carried out both according to the Customer's projects and according to their own projects developed according to the terms of reference;

- Installation supervision and start-up and commissioning works We provide installation supervision and commissioning services for all equipment supplied by us.

Design of automation systems

The specialists of Automation Department carry out a complex of works on the creation of new and expansion of existing automated control systems, which includes:

- development and approval of technical specifications for the creation of automated process control systems;

- design and development of design documentation for automated process control systems, communication systems and automated dispatch control systems;

- complete set of automated process control systems with instrumentation and control equipment, assembly of automation cabinets and instrument racks at their own production sites;

- software development of the middle and upper levels of automated process control systems;

- installation supervision and start-up and commissioning works of automated control system equipment;

- carrying out all necessary tests and trial operation of the automated process control system.

.png)

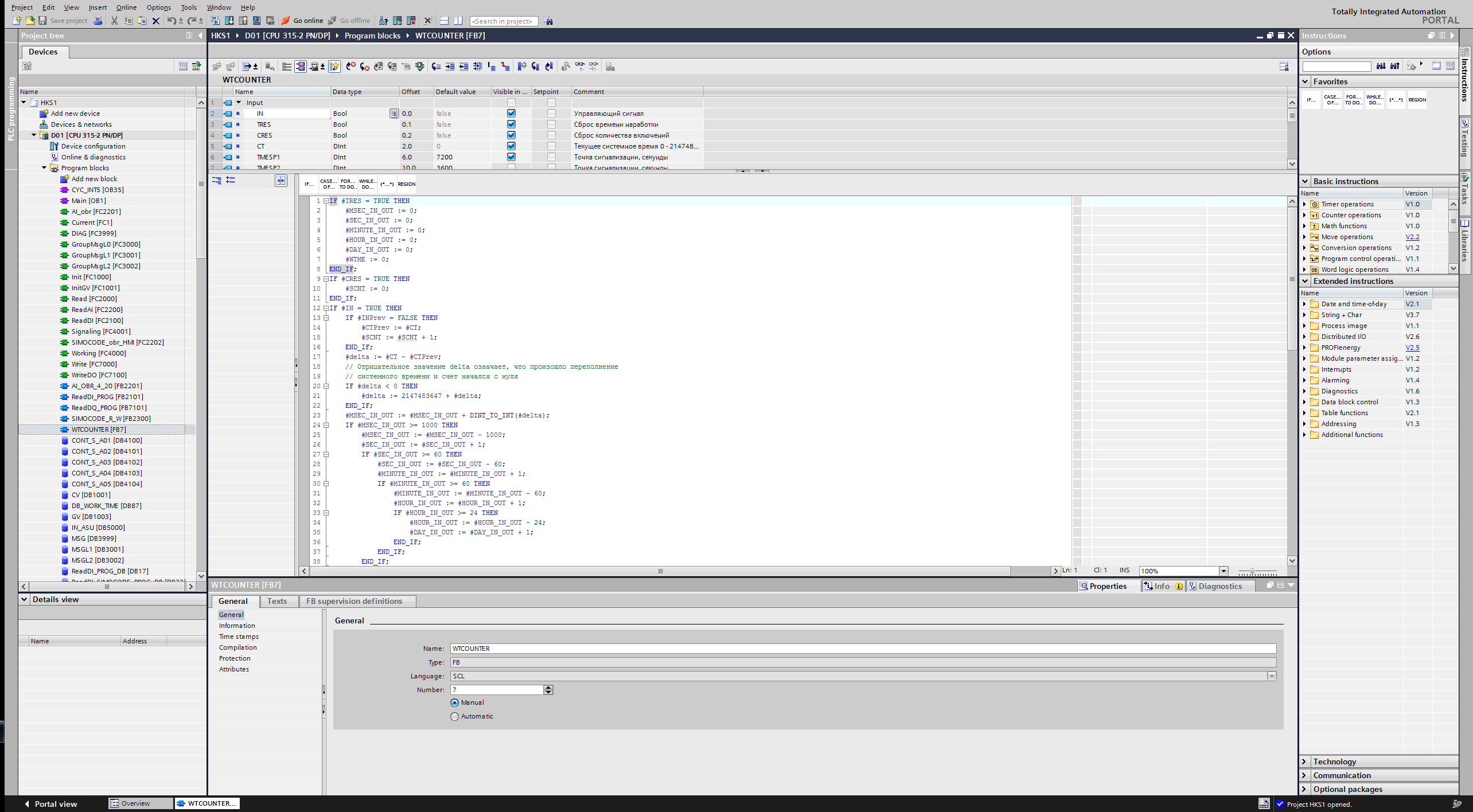

Programming

As part of automation projects, we offer a wide range of services for programming of automatic control systems of any complexity, including:

- selection of controller stations;

- programming of controllers;

- visualization programming;

- programming of SCADA systems.

The specialists of the company know products such as SIMATIC STEP 7, S7-PLCSIM, S7-SCL, WinCC flexible, SIMATIC WinCC, TIA Portal, Drive ES – STARTER, SIMOCODE ES, Schneider Electric SoMachine, Vijeo-Designer, ОВЕН SP 300 Configurator, CoDeSys and others.

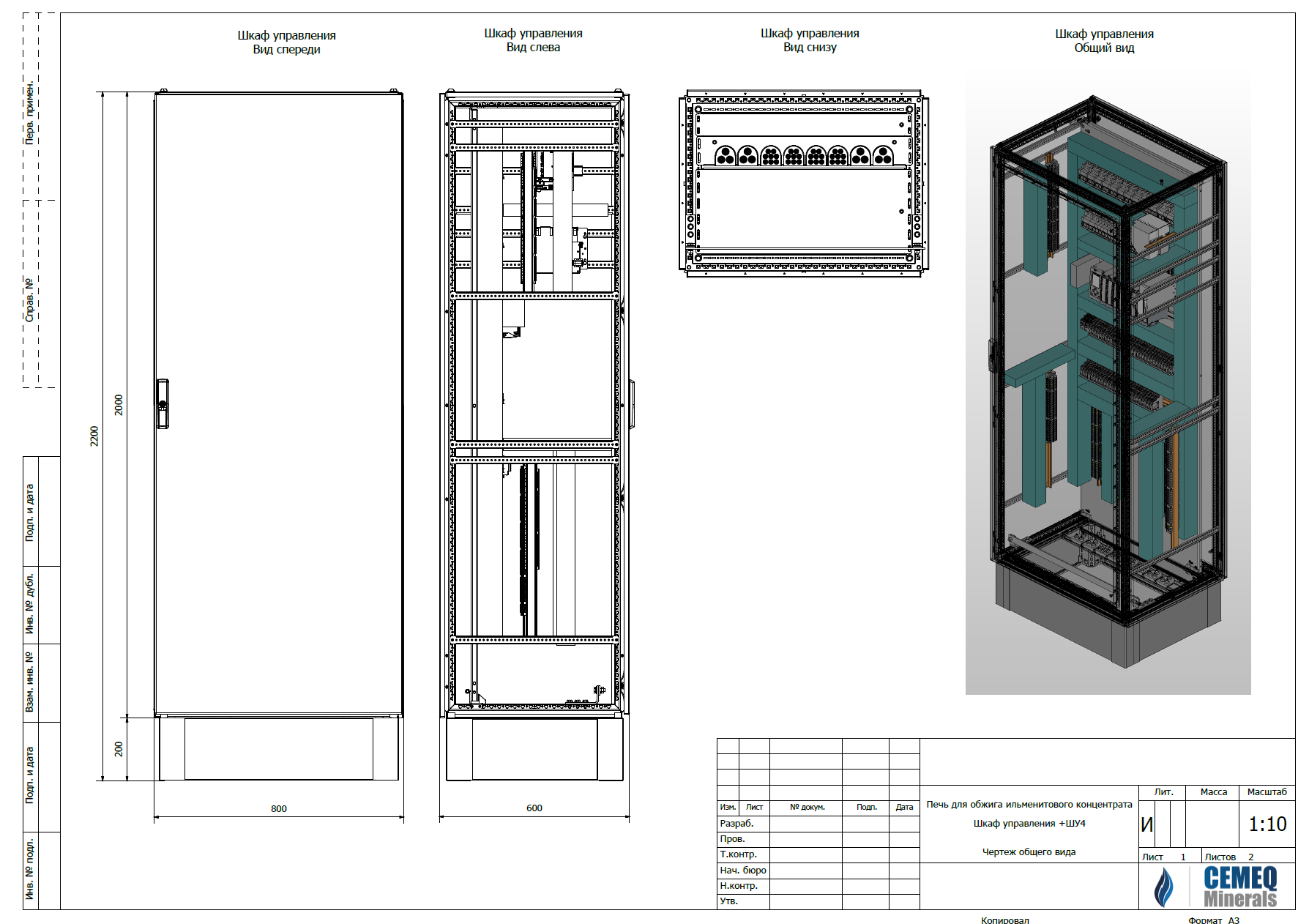

Design and manufacture of control cabinets

The specialists of Automation Department carry out the full cycle of production of low voltage complete device design and assembly according to the technical specifications of the customer:

- power cabinets and control panels designed to accommodate distribution equipment, switching and protection devices, frequency converters, start-up and power equipment;

- distribution cabinets and panels designed for receiving and distributing electrical energy;

- cabinets of automatic load transfer (ALT), designed to restore power to consumers by automatically connection of reserve power source when the main (working) source is turned off. The ALT control circuits can be implemented both on a relay-contactor circuit and on a controller.

Installation supervision and start-up and commissioning works

Our company has many years of experience in automation of technological processes in different industries and has all necessary production and engineering resources to carry out installation supervision and start-up and commissioning works during the implementation of automated process control systems of different levels of complexity.

During the installation supervision, specialists of the Automation Department supervise and provide organizational and technical guidance for the supply and installation of automated systems equipment, general technical and technological control over the progress of work, and ensure the required quality control of operations performed by the customer's specialists.

In the process of commissioning, our specialists debug and launch the complex of technical means of the automated system, check and adjust the application software, unit-by-unit and complex testing, ensure the commissioning of the automated system into trial operation, performance adjustment of the entire system and the required logical control tasks. Start-up and commissioning works are completed by conducting acceptance tests and putting the automation object into commercial operation. In the process of commissioning at the object, consultations and training of personnel of the Customer are also carried out.